VACUUM FILTERS & LIQUID SEPARATORS

Your industrial equipment is only as strong as your maintenance protocols. The functionality and longevity of every tool hangs on your ability to care for and repair it as necessary. That’s why investing in high-quality filters, silencers, and traps is a smart move. These industrial filtration products prevent airborne particles and other contaminants from entering the rest of your workspace, compromising equipment integrity and lifespan. Protecting your valuable tools from contamination is one of the smartest decisions you can make in the manufacturing business – and we’re here to help. For more information, call 02-168-3193-5 #109 or add Line ID: @multiphase (available 24 hours a day)

FILTERS & LIQUID SEPARATORS

ST/CT Series: Inline Straight-Through Vacuum Filters

ST Series: Inline See-Through Vacuum Filters with polycarbonate see-through bucket, 1” to 4”

CT Series: Inline Straight-Through Vacuum Filters with black carbon steel bucket, 1” to 6”

Specifications

- Easy maintenance due to see through bucket (ST Series)

- Compact design for space restrictions; min. service area

- Inlet above element for extended element life &

maintenance intervals - Corrosive resistant cast aluminum top with machined

connections and integrated baffle design - Black powder coat carbon steel drop down bucket (CT)

- Shatter-resistant polycarbonate drop down bucket (ST)

CSL Series: Inline Right Angle Vacuum Filters

Solberg’s CSL Series Vacuum Filters are designed for a variety of vacuum processes where harmful particulates are present. Ideal for protecting the inlet of most vacuum pumps, the CSL Series comes standard with a variety of replaceable filter element options that offer superior protection and longevity for the vacuum system.

Specifications

- Vacuum Rating: medium vacuum service

- Temp (continuous): min ‐15°F (‐26°C) max 220°F (104°C)

- Filter change out differential: 15-20″H2O (37‐50 mbar) over initial Δ P

- Polyester: 99%+ removal efficiency standard to 5 micron

- Paper: 99%+ removal efficiency standard to 2 micron

WL Series: Medium/High Vacuum

Solberg’s WL Series Vacuum Filters are designed for a variety of industrial and semicon processes where rapid thermal and/or pressure cycles create harsh operating conditions. Ideal for medium-high vacuum applications that utilize vacuum furnaces or deposition tools, the WL series comes standard with a variety of vacuum rated flange options and replaceable filter elements that offer superior protection and longevity for the vacuum system. Housings in this series are 100% helium leak tested to ensure vacuum integrity and verify leak rates down to 1x 10-5 mbar/l/s.

Specifications

- Rated vacuum leak rate of 1×10-5 mbar/l/sec or better (verified by helium leak test)

- Temp (continuous): min -15°F (-26°C) max 220°F (104°C)

- Filter change out differential: 28 – 37 Torr over initial ΔP

- Polyester: 99%+ efficiency to 5 micron

VTL/VTS Series: Chemical Adsorption Inlet Vacuum Traps

Solberg’s Chemical Traps can be used to protect a variety of vacuum pump technologies from particulate, liquid, aerosol, and vapor contaminants. Multiple insert options and configurations are available to ensure pumps are properly protected. The trap minimizes pump oil contamination resulting in significantly fewer oil change-outs and reduced maintenance costs. Solberg’s VTS/VTL Inlet Vacuum Trap Series offers multiple configurations including:

- Molecular Sieve Trap

- Steel Wool Trap

- Particulate Filter Trap

Specifications

- Vacuum service down to 1×10-3 mbar

- Leak rate: 1×10-7 mbar L/sec

- Temperature range -4°F to 302°F

- Fine bead blast finish

- Viton O-ring

HV Series: Medical Vacuum Bacterial Filter

Solberg’s HV Series bacterial filters for medical vacuum service are designed to offer industry leading pressure drop performance and meet demanding filtration requirements in accordance with current European and US medical vacuum standards:

- ISO 7396-1:2016 Medical gas pipeline systems — Part 1 Pipeline systems for compressed medical gases and vacuum

- NFPA 99:2018 Health Care Facilities Code

Specifications

- Operating pressure range: atmospheric to full vacuum

- Particulate removal > 99.995% efficiency

- Meets ISO 29463-1 requirements for ISO 45H class filtration

- Temp (continuous): min -15°F (-26°C) max 220°F (104°C)

- Corrosive resistant aluminum cast head

- Shatter resistant polycarbonate collection area

- Glass drain flask for easy removal and sterilization

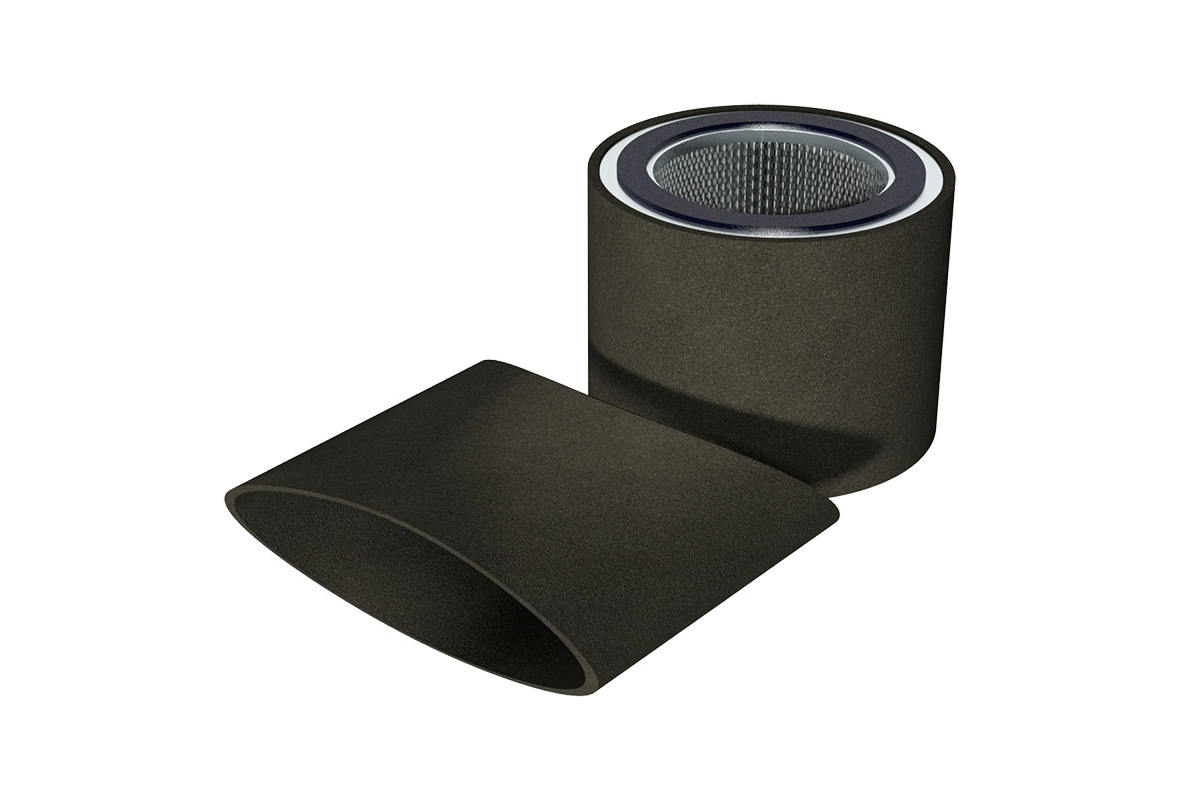

SpinMeister® ST/CT Series: Extreme Duty Filtration

Centrifugal force from intake air causes particulate to separate from air stream, forcing it to the outer cover perimeter and out through the discharge port. The SpinMeister® Precleaner eliminates large objects from entering the air stream. The air stream then enters the particulate filter (optional) and is filtered by a 99+% efficient pleated element.

- SpinMeisters® available in polished aluminum

- Various media

- Extended capacity (select models)

- Pressure drop gauge

- Carbon steel bucket versions

- Taps for gauges and mounting brackets

Specifications

- Vacuum Rating: coarse vacuum service*

- Polyester: 99%+ removal efficiency standard to 5 micron

- Paper: 99%+ removal efficiency standard to 2 micron

RST Series: Extreme Particulate Load - Reverse Pulse

The reverse pulse RST Series incorporates split second bursts of pressurized air to create a powerful shock wave that cleans the filter element and extends its service life. Quick pulses cause particulate sitting on the elements pleated surface area to release and collect in the drop out area of the filter housing. Pulses can be repeated as required and can occur during a running process because the split second air bursts have minimal effect on the process pressure. Operation can be manually controlled or automated based on user preference. (Optional pulse kit available.)

- Superior level of filtration offers enhanced equipment protection

(PTFE style elements) - Extends the life of filter element, reducing overall cost

- See-through design allows for instant visual inspection

Specifications

- Vacuum rating: medium vacuum service

- PTFE media: 0.3 micron, 99.5% efficiency

- Temperature ratings:

- Complete assembly: max 220°F (104°C)

- See-through bucket only: max 257°F (125°C)

XCSL Series: ATEX Vacuum Filters

Explosions can occur within applications such as pharmaceutical, chemical, metal, food, plastics, coal and wood working industries. Solberg was one of the first filtration companies qualified to service these industries in compliance with the ATEX directive 2014/34/EU. This European Union code seeks to minimize the possibility of explosions related to equipment used in potentially explosive gaseous or dusty environments.

Specifications

- Vacuum Rating: medium vacuum service*

- Temp (continuous): min ‐15°F (‐26°C) max 220°F (104°C)

- Filter change out differential: 15-20” H2O (37‐50 mbar) over initial Δ P

- Polyester: 99%+ removal efficiency standard to 5 micron

- Paper: 99%+ removal efficiency standard to 2 micron

- ATEX nameplate standard

STS Series: Straight Through Liquid Separator

Inlet air with potentially harmful liquid and large particulate enters the housing and is separated by a baffle mechanism and directional air flow changes. The larger particles and liquid drop down and collect at the bottom of the separator. The float capsule within the separator screen rises with the liquid level until max capacity and limits the flow, thereby protecting the pump from damage.

- Minimize the likelihood of damage to vacuum valves and

pumps from liquid - Protect installed equipment from liquid contamination by

retrofitting STS separator - Easy visual inspection with see-through housing

- Reduce piping costs with T-style configuration

- Compact design for space restricted work areas

Specifications

- Vacuum Rating: medium vacuum service

- Temp (continuous): min ‐15°F (‐26°C) max 220°F (104°C)

LRS Series: Right Angle Liquid Separator

The inlet air, with liquids and particulate that are potentially harmful to the vacuum pump, enters the highly efficient vacuum filter and is separated by an integrated baffle. The larger particles and liquid drop down to the large capacity lower chamber. The lower chamber has significant liquid/slurry holding capacity. The final stage has a replaceable filter element for particulate that is 99+% efficient before it reaches the vacuum pump.

- Multistage filtration & separation

- Protects pump from harmful liquids that break down

lubricating/sealing oil - Lower cost than individual separator and filter

Specifications

- Vacuum Rating: rough to medium vacuum service*

- Filter change out differential: 15-20″ H2O (37-50 mbar) over initial Δ P

- Polyester: 99%+ particulate removal efficiency to 5 micron

JST/JCT Series: Straight Through Vacuum Trap

JST & JCT Series vapor condensers are designed to protect equipment from harmful vapors and liquids that can break down pump oils and harm a pump’s inner workings. Vapor removal is accomplished through transitioning a substance from a gaseous state to a liquid or solid state and collecting any condensed material that accumulates.

Specifications

- Removable heat exchanger fin pack for ease of cleaning and long lasting optimum performance

- Coolant flask system

- Stainless steel demister pad

- Compact housing for minimal footprint

- Removable bottom for full accessibility

- Coolant inlet and outlet ports

- JST Series: Durable see-through bucket made from

- shatter resistant polycarbonate

- JCT Series: Corrosive resistant carbon steel bucket

VTL/VTS Series: Chemical Adsorption Inlet Vacuum Traps

Solberg’s Chemical Traps can be used to protect a variety of vacuum pump technologies from particulate, liquid, aerosol, and vapor contaminants. Multiple insert options and configurations are available to ensure pumps are properly protected. The trap minimizes pump oil contamination resulting in significantly fewer oil change-outs and reduced maintenance costs. Solberg’s VTS/VTL Inlet Vacuum Trap Series offers multiple configurations including:

- Molecular Sieve Trap

- Steel Wool Trap

- Particulate Filter Trap

Specifications

- Vacuum service down to 1×10-3 mbar

- Leak rate: 1×10-7 mbar L/sec

- Temperature range -20°C to 150°C

- Fine bead blast finish

- Viton O-ring

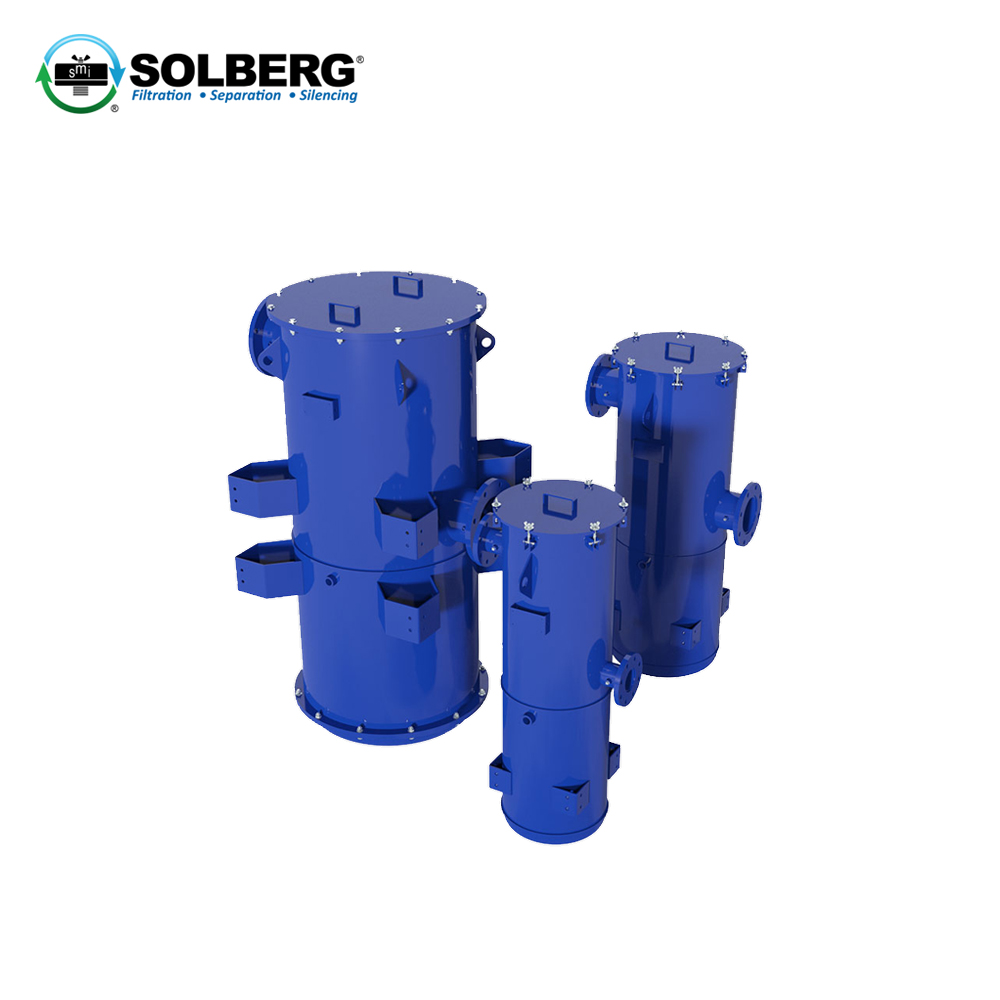

JRS Series: Multistage Separator Trap

JRS Series vacuum filter systems are designed to protect equipment from harmful vapors and liquids that can break down pump oils and destroy a pump’s inner workings. Vapor removal is accomplished through transitioning a substance from a gaseous state to a liquid or solid state and collecting any condensed material that accumulates. The wide range of applications & equipment such as the industrial & severe duty, vacuum packaging equipment, food industry, medical/hospital, chemical processing, vacuum pumps & systems etc.

Specifications

- Removable heat exchanger fin pack for ease of cleaning and long lasting optimum performance

- Coolant flask system

- Corrosive resistant blue powder coat carbon steel

- Coolant inlet and outlet ports

- 2” NPSC drain port