INLET FILTRATION AND SILENCING

Excessive noise is disruptive to a productive environment. If your workplace is dealing with distracting sounds, you need reactive, absorptive silencing solutions that keep the noise under control. That’s what our air compressor filter silencers are for. Solberg’s high-quality filter silencers deaden noise and offer exceptional performance in tough industrial environments. The compact designs are used for filtration protection, noise attenuation (silencing), and vent breather applications.

With a variety of inlet filter media options available, including polyester, paper, and wire mesh, we have the right filter to protect your equipment. Whether you need to protect fan inlets or quiet valve noise, we have something that can help. Our filtration tools move air and working components within your equipment, using reactive and absorptive silencing technologies to dampen mechanisms and silence tubes. For more information, call 02-168-3193-5 #109 or add Line ID: @multiphase (available 24 hours a day)

INLET AIR FILTER AND FILTER SILENCER

FS/PS Series: Filter Silencers for Blowers & Compressors

FS Series: Solberg’s Stamped Steel Filter Silencers remove dirt and debris at the inlet of compressors, blowers and fans. The sturdy carbon steel construction makes this blower silencer ideal for many situations. The weather-resistant design also makes it a good fit for most general-duty and heavy-duty applications

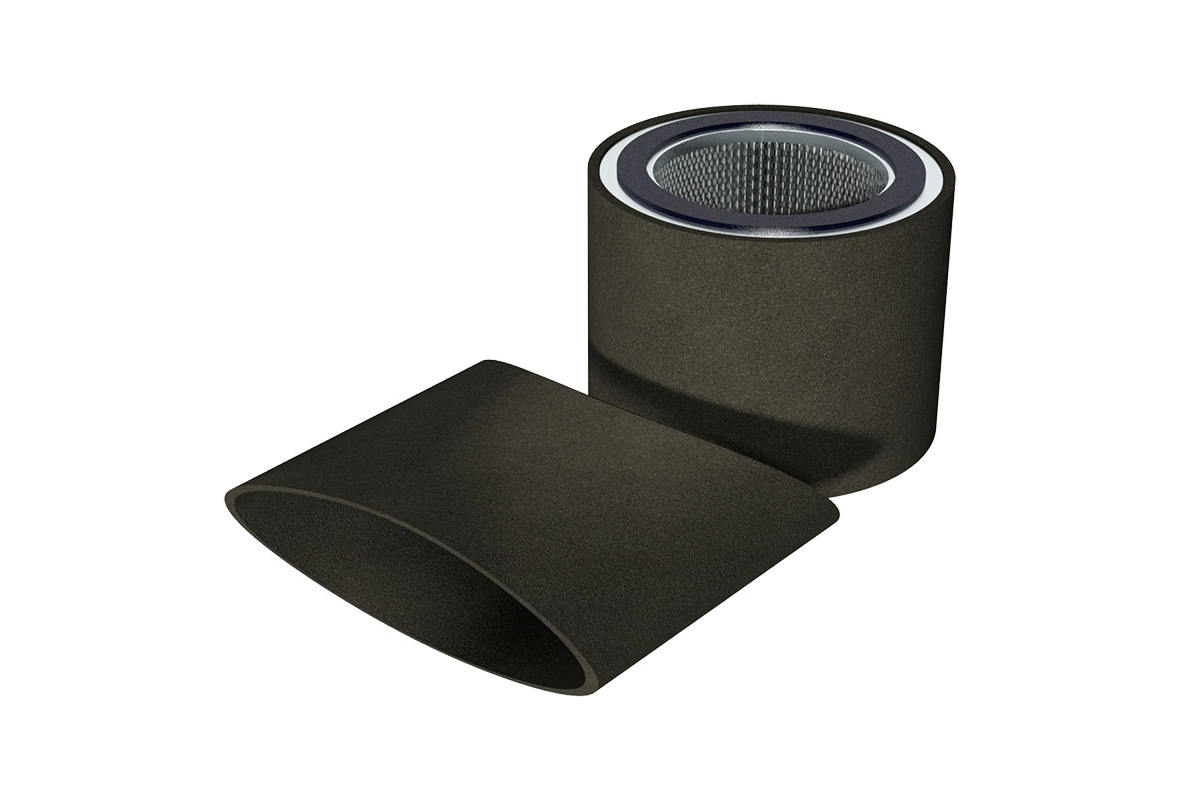

PS Series: Our Molded Polymer Filter Silencers are used on a variety of small air compressors and equipment that need basic protection in light-duty to general-duty applications. Replace just the element or the whole assembly. These compressor silencers are light weight and offer weather-resistant construction.

Specifications

- Temp (continuous): min -15°F (-26°C) max 220°F (104°C)

- Filter change out differential: 15-20” H2O over initial ΔP

- Polyester: 99%+ removal efficiency standard to 10 micron

- Paper: 99%+ removal efficiency standard to 2 micron

- Pressure drop graphs available upon request

2G/QB Series: Enhanced Filter Silencers

2G Series: This compact multi-stage premium filter silencer is readily available for North American users. Primarily used on PD blowers, the filter silencer has a compact size that minimizes the overall blower package footprint. In addition to traditional silencing tubes, the premium silencing features include a singular high flow attenuation tube in the base. The heavy-duty quiet band technology in the weather hood helps reduce noise escaping the inlet of the blower, compressor, or fan.

QB Series: This heavy-duty filter silencer has integrated silencing tubes that reduce noise attenuation. It also boasts an enhanced weather hood with quiet band technology that reduces noise escaping the inlet of the blower, compressor, or fan. It is available in metric threaded or flanged configurations.

Specifications

- Temp (continuous): min -15°F (-26°C) max 220°F (104°C)

- Filter change out differential: 15-20” H2O over initial ΔP

- Pressure drop graphs available upon request

- Polyester: 99%+ removal efficiency standard to 5 micron

- Paper: 99%+ removal efficiency standard to 2 micron

F/FT Series: Inlet Filters for Blowers & Compressors

F Series: Protect your compressor, blower or fan from atmospheric dirt and debris with this rugged inlet filter assembly. It comes standard with an all-weather hood to protect the assembly. Contact us for media options or housing coatings for harsh conditions.

FT Series: This open (exposed) element filter assembly is a space-saving option for footprint restrictive work areas.

Specifications

- Temp (continuous): min -15°F (-26°C) max 220°F (104°C)

- Filter change out differential: 15-20” H2O over initial ΔP

- Pressure drop graphs available upon request

- Polyester: 99%+ removal efficiency standard to 5 micron

- Paper: 99%+ removal efficiency standard to 2 micron

SM Series: Extreme Duty SpinMeister® Filters

Intake air is drawn through the angled louver plates which direct the air to turn the rotor. The centrifugal force separates the contaminants from the airstream, throwing them to the outer perimeter of the cover, expelling them through the discharge port. Cleaner air is drawn to the lower chamber and filtered by a 99% efficient pleated element.

- Extreme duty filtration for high dust environments

- Significantly increases life of filter element

- Cost effective

Specifications

- Temp (continuous): min -15°F (-26°C) max 220°F (104°C)

- Filter change out differential: 15-20” H2O over initial ΔP

- Polyester: 99%+ removal efficiency to 5 micron

- Paper: 99%+ removal efficiency to 2 micron

- SpinMeister® Precleaner: 85% efficiency to 15 micron