PROGRESSING CAVITY PUMPS

Modular, extremely robust, precise dosing, low pulsation. Large range of models and materials used for housings, rotor, stator, seals, joints ensures an optimum match to the medium being pumped. Our wide range of flanged connections and drives ensures the best possible solution for your installation and space. Reliability can only arise where issues are reliably thought through and acted upon. Reliable, professional and motivated work is a prerequisite in order to compete as a producer of high-quality products. This starts with development and construction and contines via production, consultancy and sales to service. For more information, call 02-168-3193-5 #109 or add Line ID: @multiphase (available 24 hours a day)

PROGRESSING CAVITY PUMPS

WANGEN KL-T | immersion pump

Thanks to the vertical construction form, the WANGEN KL-T / KB-T has only a small space requirement. The consistent diameter of the joint connections ensures constant flow speeds and reduces the sensitivity to foreign materials. The low-pulsation continuous conveying of media is independent of the pressure and viscosity.

Features

- Output: 31,5 – 560 m³/h at 350 rpm

- Free Ball Passage: up to 150 mm

Technology/Details

- flexible drive selection

- encapsulated mechanical seal, single or double acting, rinsed by the product

- robust cardan joint

- robust bearing pedestal with close-coupled drive and self-centering of the drive

- stator with s-cone inlet for optimum filling of the pumping chamber

- various geometries and pump sizes

- service-proven sealing systems

- special feed unit versions possible

- specially designed joints

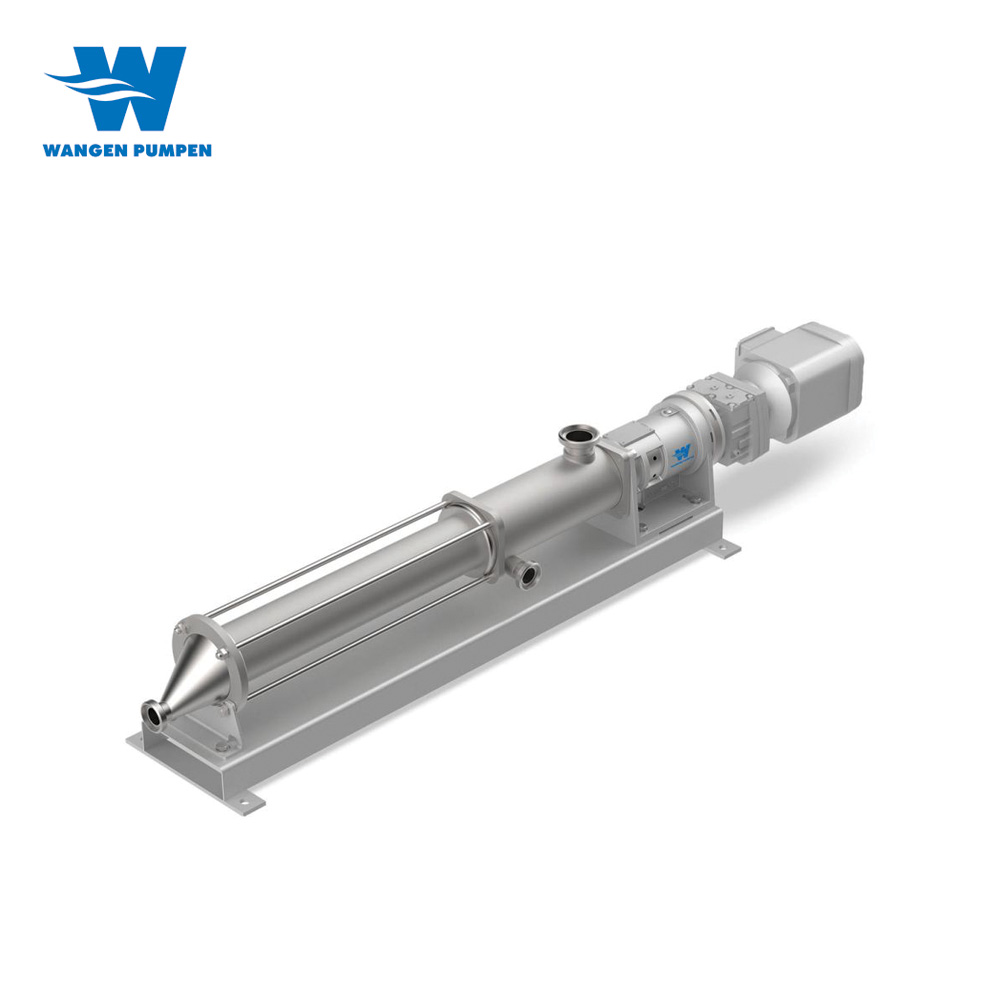

WANGEN MX-S | hygienic progressing cavity pump

For demanding hygienic conveying and dosing of aqueous to highly viscous media in the food & beverage-, pharmaceutical and cosmetics industry. Low-impact delivery of products containing solids. CIP and SIP cleaning is possible, the pump is available as a mobile or stationary unit.

Features

- Output: 1-100.000 l/h

- Free Ball Passage: up to 76 mm

Technology/Details

- stators in EvenWall® design (uniform elastomer wall thickness)

- various geometries and pump sizes

- external cut surfaces

- wear parts can be replaced quickly via a separation point opposite the product

- robust bearing pedestal for high force transduction

- materials in contact with the product: stainless steel 1.4404

- surfaces of the parts in contact with the product: Ra < 0,8 μm

- modular structure

- materials with FDA certificate on request

WANGEN KB-SL Hygienic | hygienic progressing cavity pump

The WANGEN progressing cavity pump type KB-SL Hygienic is a further development of the pump construction series for the food industry. In this area, where there is contact with the product, the stainless steel of the hygienic” version, after grinding and electropolishing, has a surface roughness of RA < 0.8 μm. Further quality characteristics are the gentle way the product is pumped, the dead-space and low stagnation space design, the high availablility as well as the low maintenance requirement. The KB-SL is available optionally with one or two tangentially inclined cleaning connections.

Features

- Output: 0.01 – 4.6 m³/h at 350 rpm

- Viscosity: up to 200.000 mPas

- Free Ball Passage: up to 24 mm

Technology/Details

- CIP (Cleaning in Place)

- encapsulated mechanical seal, single or double acting, rinsed by the product

- driven by helical geared motor

- easy cleaning thanks to construction with little dead space

- materials with FDA certificate on request

- discharge flange with self-emptying design

WANGEN KL-SL Hygienic | hygienic progressing cavity pump

The pumps of the KL-SL serie convince through their easy cleaning and minimal deadspace construction. They can run heat- or coolable. Hygienic highlights are for example CIP (Cleaning in Place) as well as low pulsation and continuous conveying, independent of pressure and viscosity.

Features

- Output: 0.01 – 150 m³/h at 350 rpm

- Viscosity: up to 200.000 mPas

- Free Ball Passage: up to 95 mm

Technology/Details

- materials with FDA certificate on request

- easy cleaning thanks to construction with little dead space

- ground, electropolished surfaces

- encapsulated mechanical seal, single or double acting, rinsed by the product

- flexible drive selection

- discharge flange with self-emptying design

- double, maintenance-free bearing

WANGEN BIO-MIX | hopper feed pump

WANGEN BIO-MIX pumps have been integrated for many years in the energy production process and undergone continuous further development and optimization. They are suitable for conveying maize silage, grass silage, GPS, solid manure, poultry dung, waste and co-ferments, which are mixed with liquid in the pump. Also available with WANGEN PUMPEN’s developed and patented X-LIFT quick change system.

Features

- Output: 30, 40, 85, 150 m³/h

Technology/Details

- fully developed, robust universal joint with pre-feeding screw

- service-proven sealing systems

- flexible drive selection

- reinforced cardan joint

- specially designed joints

- stator with s-cone inlet for optimum filling of the pumping chamber

- robust bearing pedestal for high force transduction

- suction housing with large inspection and cleaning openings

- driven by helical geared motor

- robust bearing pedestal with close-coupled drive and self-centering of the drive

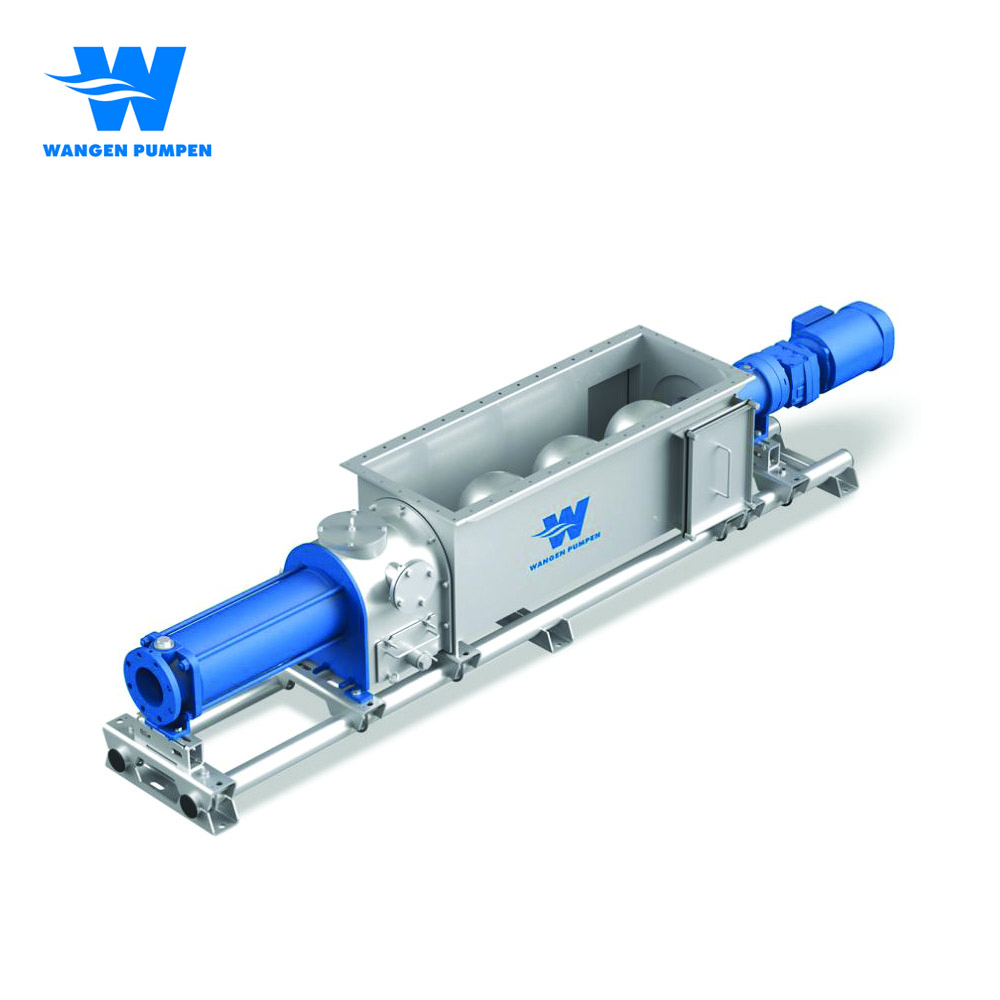

WANGEN KL-R Triplex | hopper feed pump

Pumps of the KL-R Triplex series impress with their consistent dosing option, as an intermittent input is compensated by the buffer volume in the collecting container. The small space requirement and large receiving vessel are a result of the low construction and the large volume of the container. The best pump for dewatered sludge in waste water treatment plants. Highest robust design quality. Very robust pump, ideal for pumping dewatered sewage sludge and therefore ideally suited for use in the sludge to energy sector. Developed for extra long lifespan.

Features

- Output: 0-80 m³/h (at 25-100 rpm)

- Dry Substance Content: max. 45%

- Free Ball Passage: up to 121 mm

Technology/Details

- enlargement possible with add-on funnel

- continuous flow rates at high counterpressure up to 48 bar

- robust bearing pedestal with close-coupled drive and self-centering of the drive

- flexible drive selection

- fully developed, robust universal joint with pre-feeding screw

WANGEN MX-R Triplex | hygienic hopper feed pump

The trough shape of the hygienic WANGEN MX-R pump prevents deposits from forming on the hopper walls, overfeeding in the pump tunnel ensures efficient conveying.

Features

- Output: 5-100000 l/h

- Free Ball Passage: up to 76 mm

Technology/Details

- stators in EvenWall® design (uniform elastomer wall thickness)

- modular structure

- reliable delivery of the medium to the pump assembly thanks to stable screw conveyor shortly before the pump assembly

- easy cleaning thanks to construction with little dead space

WANGEN BIO-FEED | self-priming pump

With a specially-developed milling screw, you can mix the solids that are to be added with the separately added liquid and convey it into the desired containers. With our innovative X-LIFT quick-change system, the wearing parts are easy to replace. Only a few simple steps are needed, without this requiring disassembly of the pump from the piping system. Thereby, WANGEN BIO-FEED is also suitable for use in restricted spaces. Due to the pushing of the screw connection, WANGEN BIO-FEED turns into a high-performance suction pump. You can use it as a central pump in your biogas plant. To simplfy integration into your conveyor, our WANGEN BIO-FEED’s pump body is equipped with two DN150 connections bearing bracket side, one DN400 connection for the screw conveyor and two DN200 at stator side. In addition, you can use these as cleaning openings and for rinsing the mixing chamber.

Features

- Output: up to 50 m³/h

- Dry Substance Content: 15 %

- Free Ball Passage: up to 112 mm

Technology/Details

- connections: 2 x DN150 at bearing braket side, 1 x DN400 for connection of screw conveyor, 2 x DN200 at stator side

- modern sealing system (LWD mechanical face seal)

- fully developed, robust universal joint with pre-feeding screw

- flexible drive selection

WANGEN Xpress | self-priming pump

The changing of wear parts with very few actions, without removing the pump from the pipeline system thanks to Service in Place.

The WANGEN Xpress pump range has been specially developed for easy maintenance and to considerably shorten the servicing time and thus reduce costs. Reliable pumping of media, along with fast rotor/stator changes are ensured by the patented X-LIFT quick change system developed by WANGEN PUMPEN. The X-LIFT flange is constructed on standard flange design principles. Available in the sizes 48, 64, 78 and 94.

Features

- Output: up to 102 m³/h / 449 gpm

- Temperature: max. +60°C

- Viscosity: up to 20.000 mPas

- Dry Substance Content: max. 8%

- Free Ball Passage: up to 73 mm / 2.87 inch

Technology/Details

- fully developed, robust universal joint

- service-proven sealing systems