PRIMEROYAL SERIES

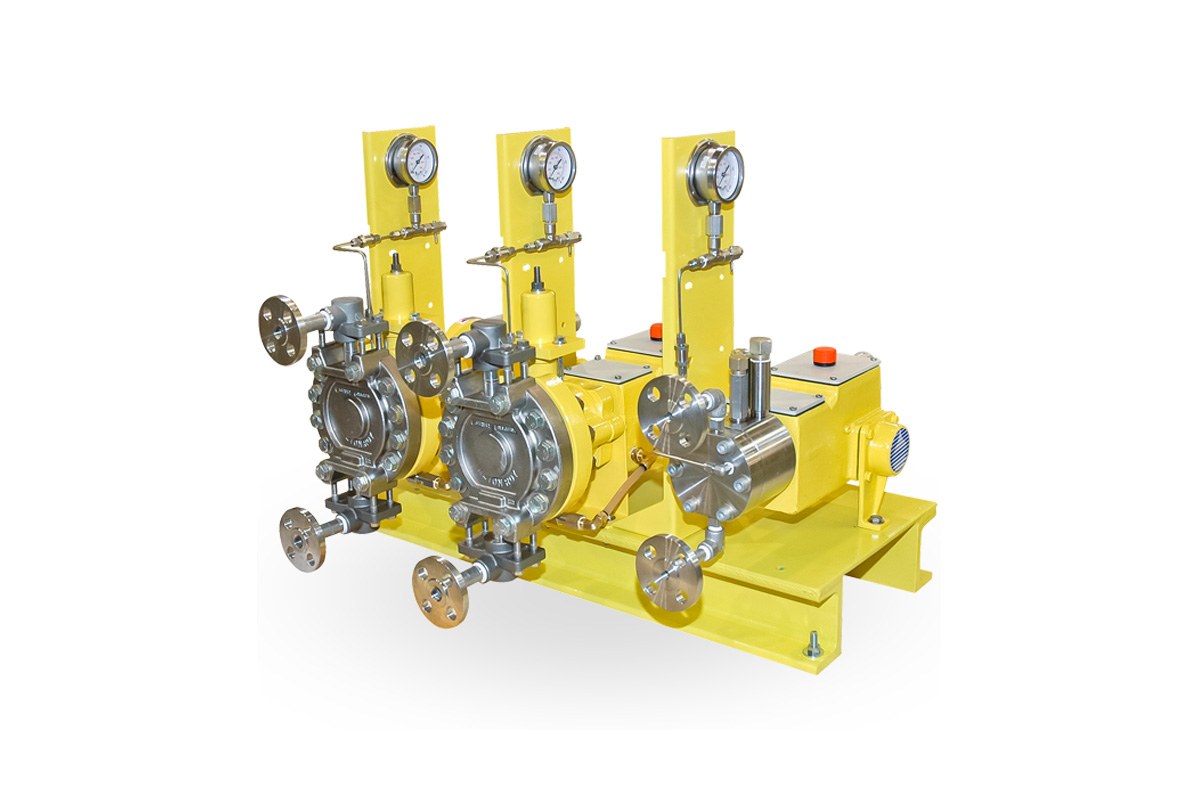

The outstanding reliability of PRIMEROYAL® series pumps begins with a robust gear mechanism and a modular design. These highly flexible pumps accept several types of liquid ends and capacity-control options for the specific requirements of your application. With more than fifty years of experience and advanced pump-engineering technologies, PRIMEROYAL® metering pumps provide continuous operation with the longest possible time between scheduled maintenance. The combination of robust, field-proven design and flexible modularity makes PRIMEROYAL® pumps suitable for a large number of industrial processes. The PRIMEROYAL® range provides accurate dosing of a broad spectrum of fluids at flow rates that can reach more than 6,853 gph (25,941 L/h) in the triplex configuration. For more information please call 02-168-3193-5 #109 or Line ID: @multiphase

PRIMEROYAL SERIES

PRIMEROYAL SERIES

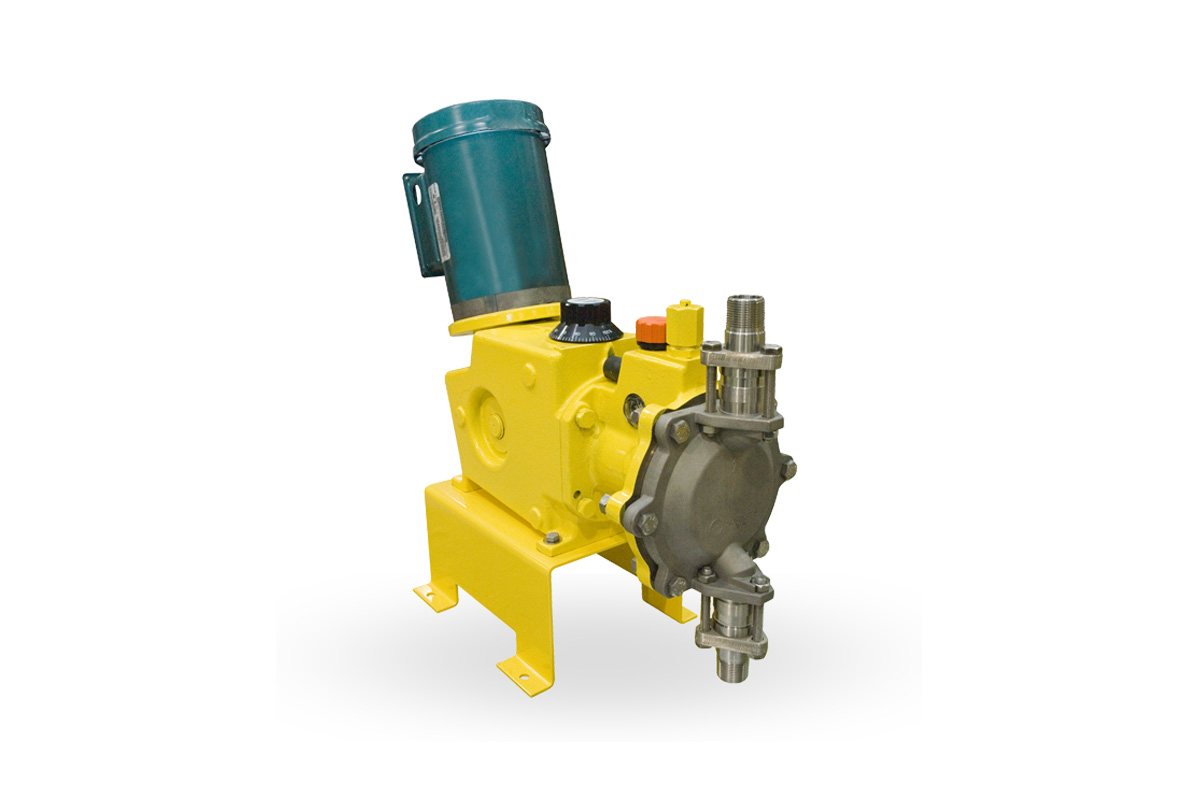

High-Pressure Metering Pump

PRIMEROYAL® metering pumps are versatile, reliable pumps that consistently and accurately inject chemicals. The pumps’ fieldproven design enables precise control of the pump delivery rate with a +/-1% steady state accuracy, over a range to 10 to 100% of the nominal flow rate, and repeatability. They feature a compact, variable eccentric drive that changes the stroke length by changing the position of the center of the shaft in the centric this API675-compliant pump has been designed to deliver maximum performance within a minimized footprint.

Specifications

- Flow rate: from 0.05 gph (0.2 L/h) to 3,315 gph (12.5 m3/h) in simplex configuration

- Pressure: up to 15,000 psi (1,034 bar) in standard

- Multiplexable

- Accuracy: ±1%, even for low flow rates and high pressures

- Fluid temperature: from -22°F to 230°F (-30°C to 110°C) as standard/up to 600°F (315°C) on request

- Ambient operating temperature: from -40°F to 122°F (-40 °C to + 50 °C)

- Stroke adjustment: from 0 to 100% of nominal flow rate

- Explosion-proof version: conforming to ATEX CE EX II 2 G/D c T3 or T4 upon request

- Standard liquid-end materials include: 316L, PVC, 17-4ph, and Alloy 20

Benefits

- Adaptability and accuracy: capacity adjustable while running or stopped (stroke micrometric adjustment, 10 turns only from 0 to 100%)

- Space constraints: Available in vertical or horizontal motor configurations

- Suitable for the majority of fluids and a large number of industrial processes: several stroke speeds for an accurate dosing

- Modular design to precisely fit your needs: more than five designs of liquid ends, specific check valves, adaptable connection types, control…

- Multiplexing capability: to reduce pulsations, meet a specific flow rate by reducing the number of parts, the power consumption and the footprint or to inject several products

Applications

- Oil and Gas Chemical Injection

- Chemical and Petrochemical Processing: Dosing catalysts for polymerization of polyethylene

- Power Generation: High-pressure boiler feed water treatment

- Refinery: Pumping of hydrocarbons/condensate

- Water Treatment in Oil & Gas: Deep water disposal, hydrocarbon condensate transfer