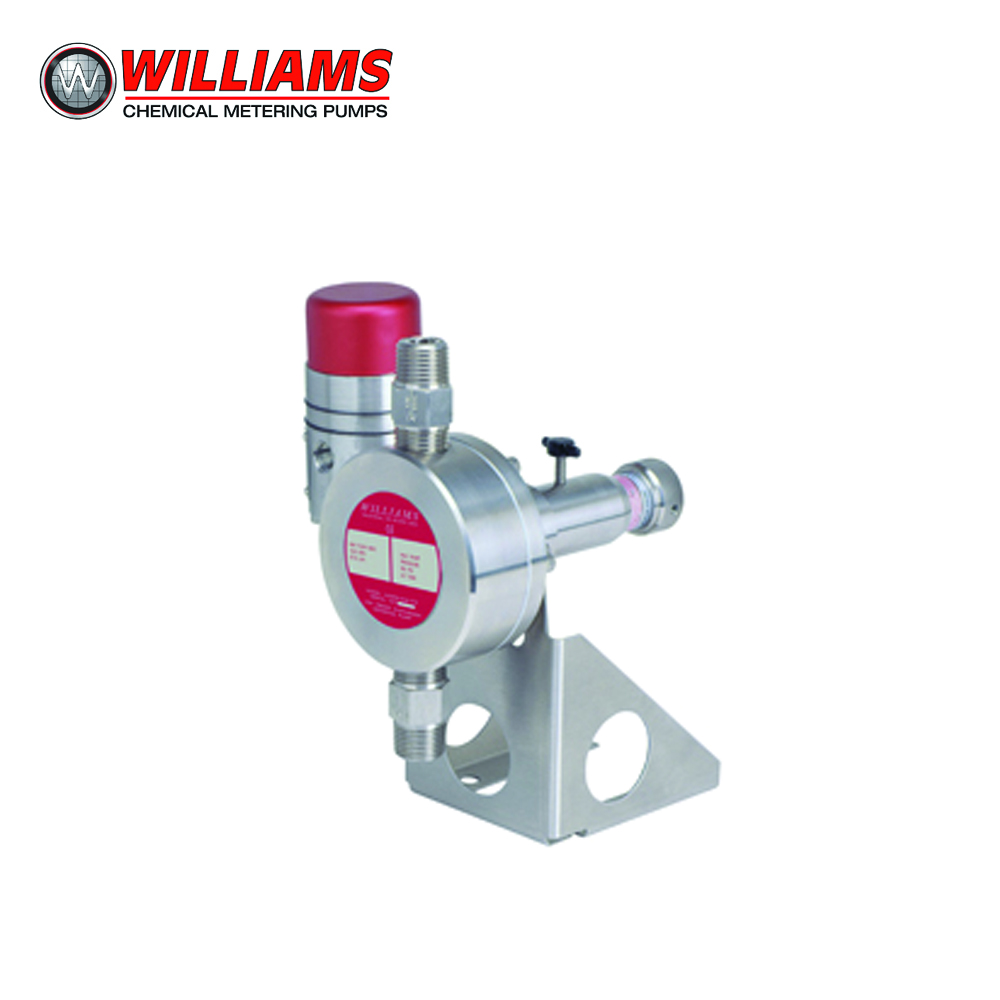

CLD SERIES LOW PRESSURE DIAPHRAGM PUMPS

The Williams lines of pneumatic metering pumps are ideally suited to precisely inject a wide variety of chemicals designed to meet your specific requirements. Made from 316 stainless steel materials which offers superior chemical compatibility and resistance, whether low volumes or high pressures let us select the right pump for you? Plunger, diaphragm, or hydraulically actuated diaphragm pumps are available all include the MK XIIA Controller which generates pneumatic pulses to stroke the pump. For more information, call 02-168-3193-5 #109 or add Line ID: @multiphase (available 24 hours a day)

CLD SERIES

CLD Series

Low Pressure Diaphragm Pumps

The CLD Pneumatic diaphragm metering pump consists of a liquid chamber and an air chamber separated by a diaphragm. The CLD is a pneumatic driven low-pressure diaphragm metering pump designed for use in low pressure chemical injection applications such cooling towers and low-pressure processes where isolation of the chemical is required.

Features

- Simple design

- Easy to maintain

- Intrinsic safety of pneumatic operation

- Stroke length and stroke rate adjustment

- High-flow turndown

- Corrosion resistant construction

- All 316 SS or TFE wetted parts

- Easy of installation