5 MAIN TYPES OF BLOWERS

5 MAIN TYPES OF BLOWERS

The beginnings of modern blowers go back to the mid-1800s, with engineering brothers Philander and Francis Roots. In an attempt to repair a water motor, one brother spun a motor’s shaft, and this caused the impellers to spin, creating so much air that the other brother’s hat flew off. An iron foundry superintendent witnessed this and pointed out that he could use this machine to melt iron. Inspired, the Roots brothers created their first blower. Today, blowers ventilate mines, charge internal combustion engines, and perform many other tasks. There are six main kinds of blowers, each with specific characteristics and uses.

1. Positive Displacement / Rotary Lobe Blowers

A positive displacement blower has a function that’s straightforward yet effective. Air or gas enters through an expanding section on one side and exits through a decreasing section on the other side. To put it simply, positive displacement blowers trap and then release the air. Positive displacement blowers maintain a constant speed and flow regardless of changes in pressure. You can use these blowers to move both air and neutral gases. If the discharge valve is closed, positive displacement blowers will continue to flow and could burst the line. That’s why safety valves are crucial for this blower.

One type of positive displacement blower is the Rotary lobe blowers which consist of two rotors spinning in opposite directions. The blower sucks in air, and the lobes spin the air around before pushing it out. One of the best aspects of rotary lobe blowers is they produce a high volume of air, which is crucial for vacuum systems. However, this air has low pressure (about 15 psi), so a rotary lobe blower is not the best choice for applications that require high pressure. Another benefit to rotary lobe blowers is that they take little maintenance and work with most blower systems. But they do let some air escape, so they are not the most energy-efficient blower option. They are incredibly loud but can be quieted with silencers.

2. Helical Screw Blowers

Each helical screw blower has a main rotor with two lobes. This rotor fits into the flute of a second rotor. The two rotors turn in a helical pattern that is carefully timed so they do not contact each other. Helical screw blowers typically produce air at higher pressures than rotary lobe blowers do. They also perform more quietly than rotary lobe blowers. These intricate blowers are energy-efficient options as well. The sealed design of helical screw blowers leads to a smooth air flow and limited air leakage. Helical screw blowers are used to move both air and gas, depending on the application.

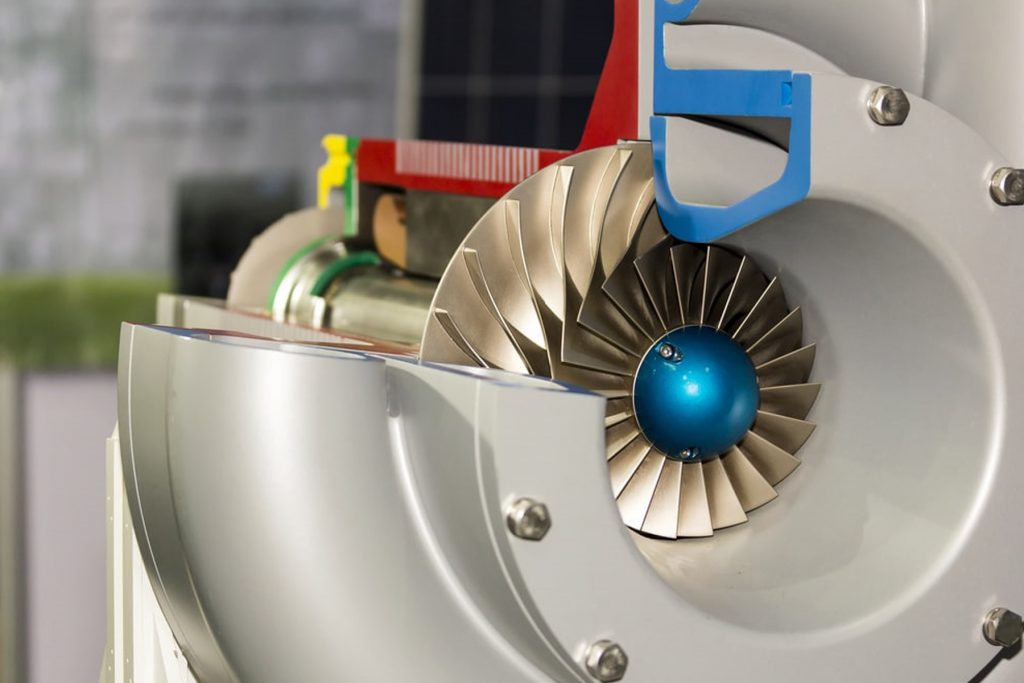

3. Centrifugal Blowers

Centrifugal blowers are the most common blowers used in ventilation systems. They’re also used to transport gas and control air pollution. When an air stream passes through this blower’s rotating impellers, it increases in both speed and volume. Centrifugal blowers actually change the airflow’s direction as well. The air or gas enters the fan wheel, turns 90 degrees, and speeds up before exiting the blower. A centrifugal blower is an ideal tool to maintain a continual gas transfer. When gas passes through a centrifugal blower, it increases in kinetic energy. When the gas exits the centrifugal blower, new gas enters to normalize the gas pressure. One specific kind of centrifugal blower is called a multistage centrifugal blower. This blower is used for creating pressure, circulating air, and creating suction. It can handle high pressure and high flow rates and is ideal for creating high pressure from small volumes of air. You can use it for fish tank aeration, gas meter testing, and even powering artificial lungs.

4. High Speed Blowers

If you need a blower with a significantly high pressure and flow, look for a high speed blower. These electrical blowers run via a motor. They have impellers at each side of the shaft to provide double suction. High speed blowers can reach a pressure up to 25 psi and a flow up to 15,000 m3 per hour.

5. Regenerative Blowers

Regenerative blowers create pressure by displacing air molecules. The impeller spins to draw in and then capture the air between every blade. As the impeller continues to spin, it pushes the air forward, where it goes back to the bottom of the blade. These types of blowers are good choices if you need to move large air volumes at a low pressure. Plus, they are easy to maintain because they are self-lubricated and contain no oil. Oil-free blowers are important if you don’t want oil released in the air. They are especially important in sensitive environments like food manufacturing facilities and hospitals.

Blowers are ideal for aeration, combustion, transportation, and many other functions. The differences between various blower types are small yet significant. Use these guidelines to choose the perfect blower for your needs.

Cr. https://www.compressor-pump.com/5-main-types-blowers/