TWIN SCREW PUMPS

Non-contact feed screw operation, efficient, compact. Developed to reliably convey low to highly viscous, volatile or gaseous products. Its design avoids dead space and stagnation zones. Due to their high speed range, they can be used as a process pump and as a cleaning pump. Changing spindles has always involved lengthy and stressful work with conventional industry solutions, associated with time-consuming and relatively high-cost service work, as the spindles always needed to be re-synchronised. This is now a thing of the past, thanks to fast-X-change® technology, developed by WANGEN PUMPEN. For more information, call 02-168-3193-5 #109 or add Line ID: @multiphase (available 24 hours a day)

TWIN SCREW PUMPS

WANGEN Twin NG | hygienic twin screw pump

The new generation of the WANGEN Twin NG screw pump is part of the hygienic pumping solutions from WANGEN and was designed to reliably pump low to highly viscous, volatile or gaseous products and for applications where maximum hygiene and efficiency is required.The hygienic pump for food and beverages, chemicals and cosmetics. Available as 3A authorized version (WANGEN Twin NG 70, 104, 130) or EHEDG certified version (WANGEN Twin NG 70, 104, 130, 180).

Features

- Output: up to 200 m³/h

- Temperature: max. +130 °C

- Viscosity: up to 1.000.000 mPas

Technology/Details

- service-proven sealing systems

- flexible drive selection

- ground, electropolished surfaces

- large variety of flange connections

- various mechanical seals as standard versions

- CIP (Cleaning in Place)

- easy cleaning thanks to construction with little dead space

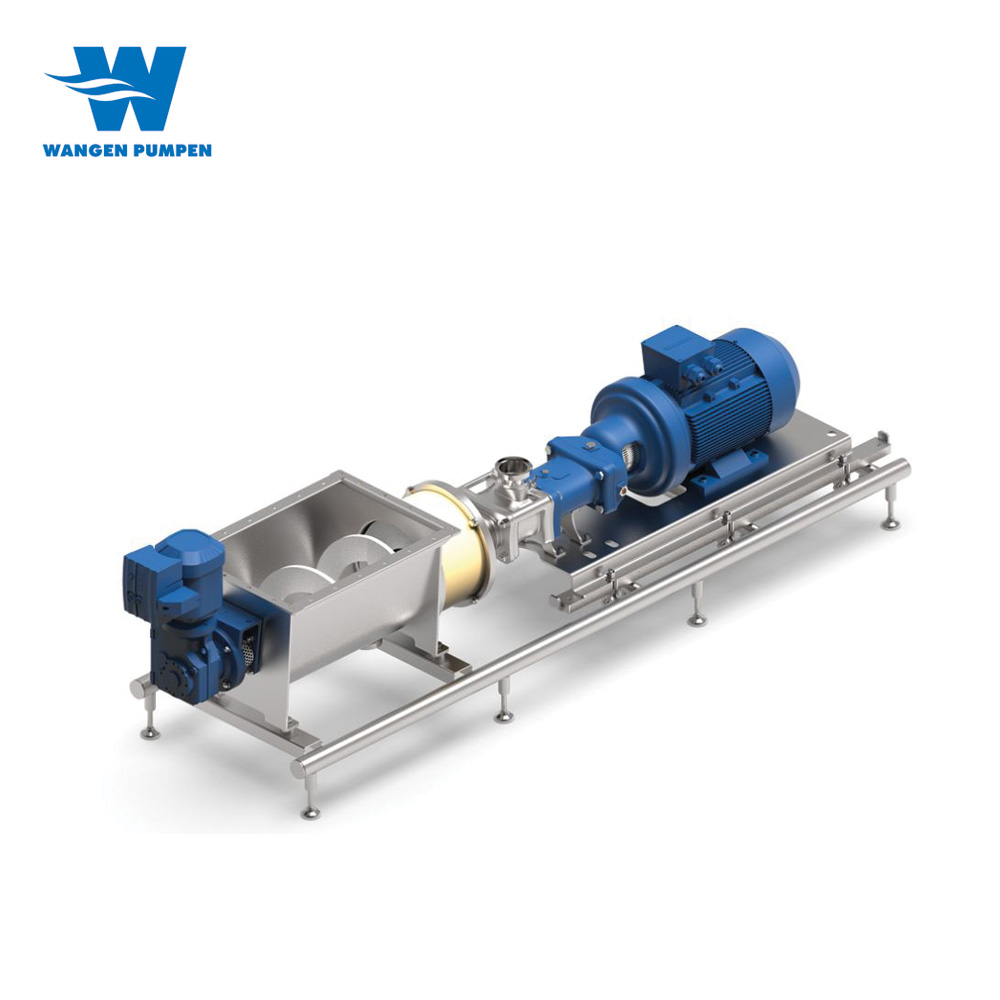

WANGEN VarioTwin NG | hygienic twin screw pump

The VarioTwin is the ideal feeder unit to pump highly viscous, not flowable media for the series 104 and 130 of the WANGEN Twin NG. This is due to the forced conveying of the pumped media via the feed screw. To cover the widest possible range of applications, the length of the hopper can optionally be designed at various levels. Therefore, the name VarioTwin was chosen.

Features

- Output: max. 10 m³/h

- Temperature: max. +90 °C

- Viscosity: up to 3.000.000 mPas

Technology/Details

- hopper available in variable length, optimally balanced to meet the field of application and requirements.

- ‘coreless’ screw conveyor enables to return excess material.

- particularly gentle feeding

- simple, effective cleaning

- drive of feed screw in the hopper can be regulated separately.

- s-cone adapter element. Connects the feed unit with the WANGEN Twin. Suitable for the Twin 104 and 130.