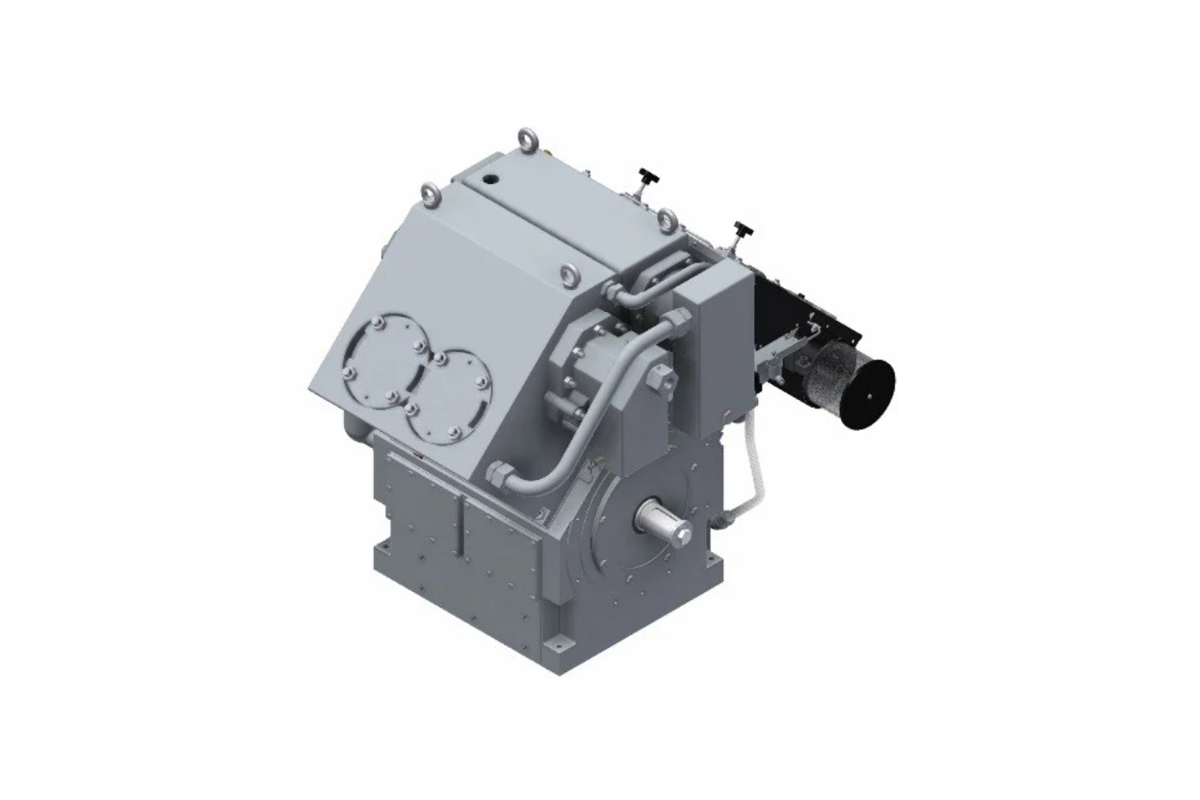

REAVELL 5400 COMPRESSORS RANGE

The 5400 series is Reavell’s range of 3 and 4 stage, high-capacity, lubricated compressors. Available in direct or “V” drive, the 5400 series is capable of reaching speeds of up to 1800 rpm; providing a pressure range from 85 bag(g) up to 414 bar(g); allowing operators to choose between maximizing efficiency or minimizing the compressors physical footprint. For more information, call 02-168-3193-5 #109 or add Line ID: @multiphase (available 24 hours a day)

REAVELL 5400 SERIES

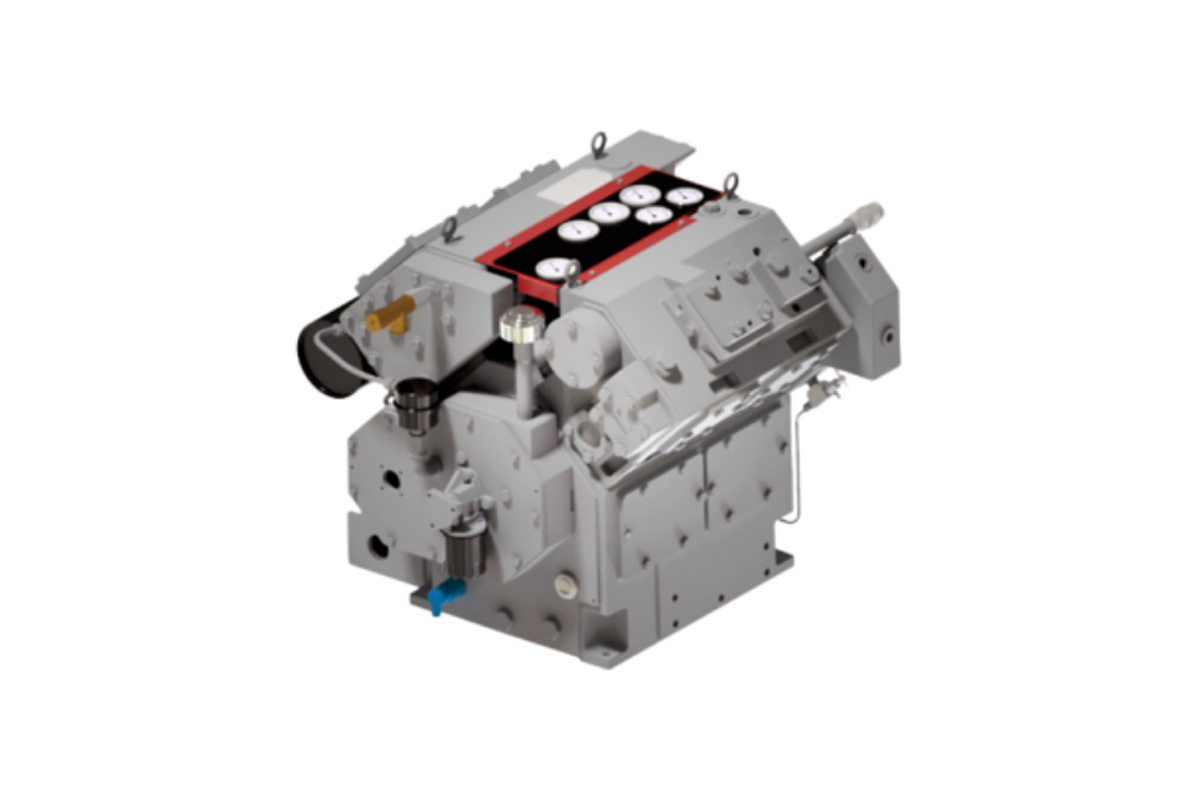

REAVELL 5400 SERIES

The compact design and high efficiency operation make the 5400 series ideal for a range of applications; including laser cutting, component testing, CNG refilling stations, and gas storage applications. With cooling systems built in, the 5400 provides a simple, plug-and-play solution that can be tailored to meet operational needs. With a wide range of performance options, ensuring integration with a variety of systems, you can be sure that Reavell has the high pressure air compressor solutions to fit your requirements. Shown here are a small selection of our compressor modules, and their reliability, maintainability, and flexibility.

Features

- Increased capacity in a relatively small footprint

- Can be configured as a two or three stage booster

- Elevated suction pressure of up to 6 bar(g)

- Air or water cooled options available

- Available with either a direct of “V” drive motor

Applications

5400 series – air cooled – 85barg to 414barg – 5404, 5405, & 5405E & 5407 & 5409 Commonly used in:

- Laser cutting

- Component testing

- Checking pressure vessels and other fittings under pressure

- Checking pneumatic controls and other fittings under pressure

- Checking brakes and other components under pressure

- Checking injection systems under pressure

- Checking gas tightness of components using helium

5400 series – water cooled – 138barg to 414barg – 5417 & 5437 Commonly used in:

- CNG refilling stations

- Biogas environments

- Water treatment companies

- Cattle and pig farms

- Land fill sites

- Gas distribution network operators

- Tin / aerosols cans – Aluminium can forming and extrusion

- Plastic forming – Nitrogen – Internal gas-pressure procedures

- Plastic forming – Isostatic forming

- Air and gas distribution

- Electrical sub station

- Air and gas distribution