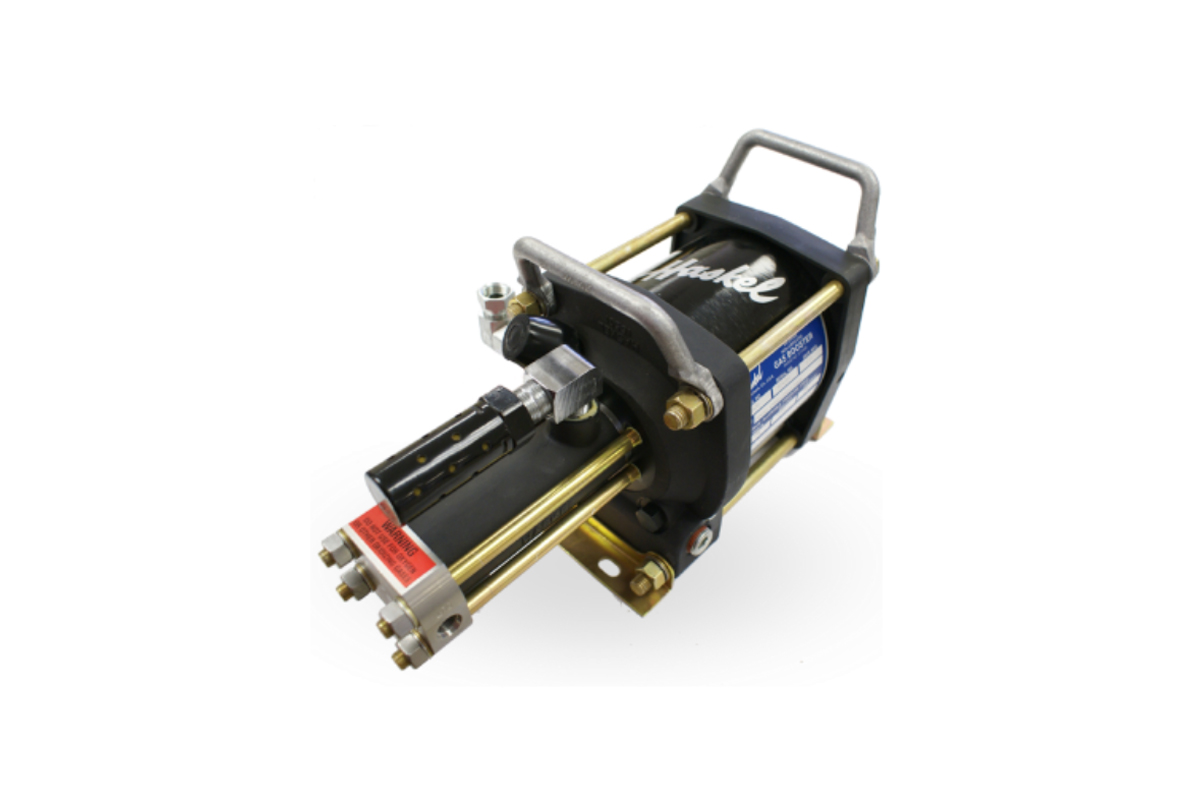

PNEUMATIC DRIVEN GAS BOOSTER

Haskel Gas Boosters consist of a large area reciprocating air drive piston directly coupled by a connecting rod to a small area gas piston. The gas piston operates in a high pressure gas barrel section. Each gas barrel end cap contains high pressure inlet and outlet check valves. Varying applications require many different booster and horse power (HP) combinations. Haskel can assist with HP and Cooling requirements and provide circuitry assistance on the following issues: PID Control – review and advisement, electrical control, and heat exchanger recommendations. General HPU recommendations and guidelines are available from Haskel drawing 87100-TAB. The air drive section includes a cycling spool and pilot valves that provide continuous reciprocating action when air is supplied to the air drive inlet. The ratio between the area of the air drive piston and the gas driven piston is indicated by the number in the model description and approximates the maximum pressure the gas booster is capable of generating. Isolation of the gas compression chambers from the air drive section is provided by three sets of dynamic seals. The intervening two chambers are vented to atmosphere. This design prevents air drive contamination from entering the gas stream.

PNEUMATIC DRIVEN GAS BOOSTER

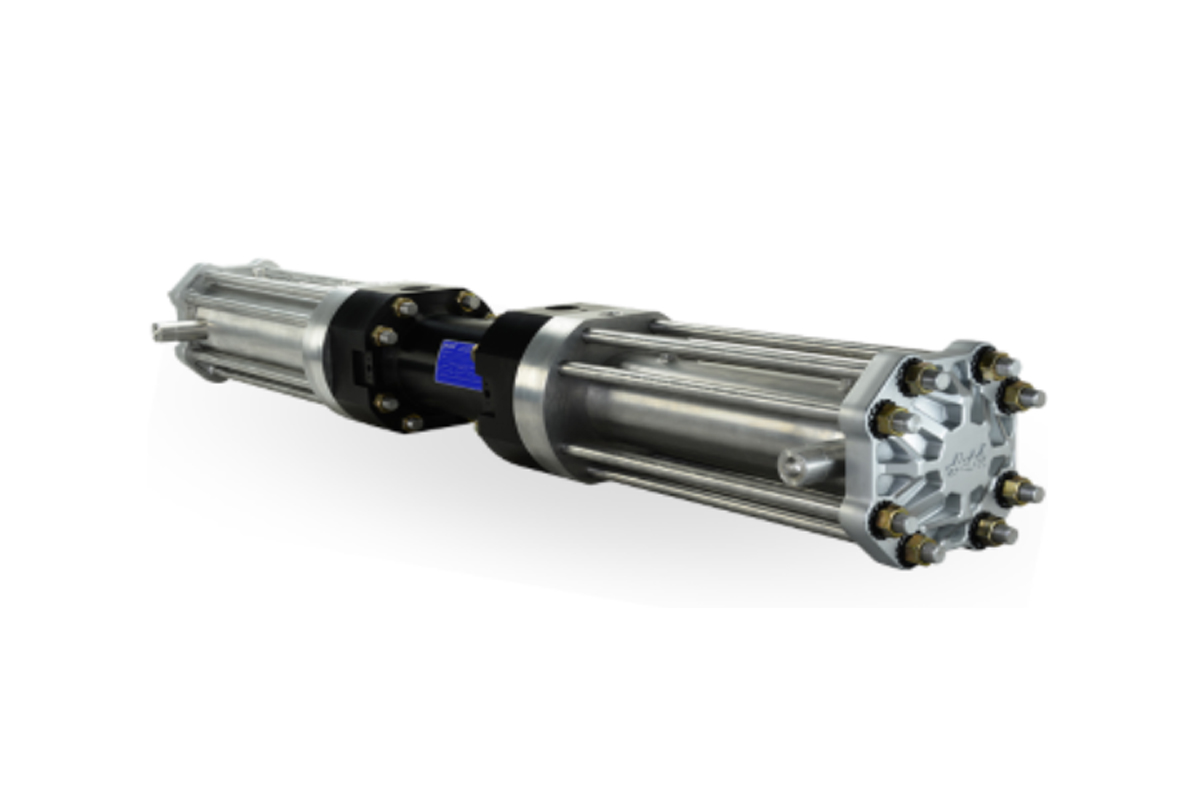

AG SERIES - GAS BOOSTER

Haskel designs and manufactures gas boosters that are the industry benchmark for durability, safety and reliability. Used for virtually all industrial gases and ideal for gas pressure increases, high pressure gas transference, cylinder charging, and scavenging, Haskel pneumatic-driven gas boosters can produce pressures up to 39,000 psi (2690 bar). Our global reputation of providing the most reliable gas boosters in various industries is backed by a global network of high pressure expertise, service and support.

Features

- Reliable, easy to maintain, compact and robust

- No heat, flame or spark risk

- Infinitely variable cycling speed and output

- Pneumatic driven models do not require electrical connection

- Easy to apply automatic controls

- No limit or adverse affect to continuous stop/start applications

- Seal systems designed for long working life

- No airline lubricator required

- Hydrocarbon free – separation between air and gas sections

- Pressures to 39,000 psi (2690 bar)

- Built-in cooling (most models)

- Standard & custom systems available

- Suitable for most gases

- Single, double acting, and two-stage models

- Ability to stall at any predetermined pressure and hold the fixed pressure without consuming power or generating heat