VACUUM PUMP DISCHARGE & AIR/OIL SEPARATION

Oil-sealed vacuum pumps discharge oil mist and “smoke” during operation. This can leave an oily residue on surfaces and spread unpleasant odors throughout the work environment. Failing to capture these emissions wastes valuable pump oil and reduces workplace safety. Solberg designs and manufactures oil mist eliminator solutions to protect your equipment and work environment. Our oil mist filters and air/oil separators help you capture and recover vacuum pump oil for reuse. Talk to us about finding the right industrial filter to extend the life of your vacuum pumps and other equipment. For more information, call 02-168-3193-5 #109 or add Line ID: @multiphase (available 24 hours a day)

VACUUM PUMP AND OIL MIST FILTERS

HB Series: Hydraulic Breathers

Solberg’s Breathers are designed to protect hydraulic tanks, lube oil reservoirs, gearboxes and other enclosures that need bidirectional venting. Our line of breathers improve flow dynamics, reduce noise, help maintain fluid purity, and minimize oil migration to the surrounding environment. Keep your system free of contaminates and maximize uptime with Solberg’s Breathers.

- Toolless design

- Ease of maintenance

- Equipment protection

- Noise reduction

- Compact designs

Specifications

- Temp (continuous): min -15°F (-26°C) max 220°F (104°C)

- Breather change out differential: 15-20” H2O over initial ΔP

- Pressure drop graphs available upon request

- Polyester: 99% removal efficiency

- Cylindrical style cartridge 5 micron rating

- Hockey Puck style cartridge 10 micron rating

HDL Series: Industrial Oil Mist Filters

HDL Series: Industrial Oil Mist The HDL series removes oil mist and aerosols from the discharge of vacuum pumps. Rugged construction, coalescing media options, and Solberg technology make the HDL a proven solution to safeguard work areas from environmentally hazardous oil mist and smoke.

- Easy field maintenance

- Pleated filter element provides increased surface area for low back pressure separation of ultra-fine oil mists

- Waste oil can be recycled

Specifications

- 0.3 micron media; 99.97% efficiency

- Continuous operating temp: 68°F (20°C) to 180°F (80°C)

- Mounted vertically

- Pressure rating (3″ – 8″, DN125-200 sizes): 7.25 psi (0,5 bar)

- Pressure rating (1″ – 2.5″ sizes): 5 psi (0,35 bar)

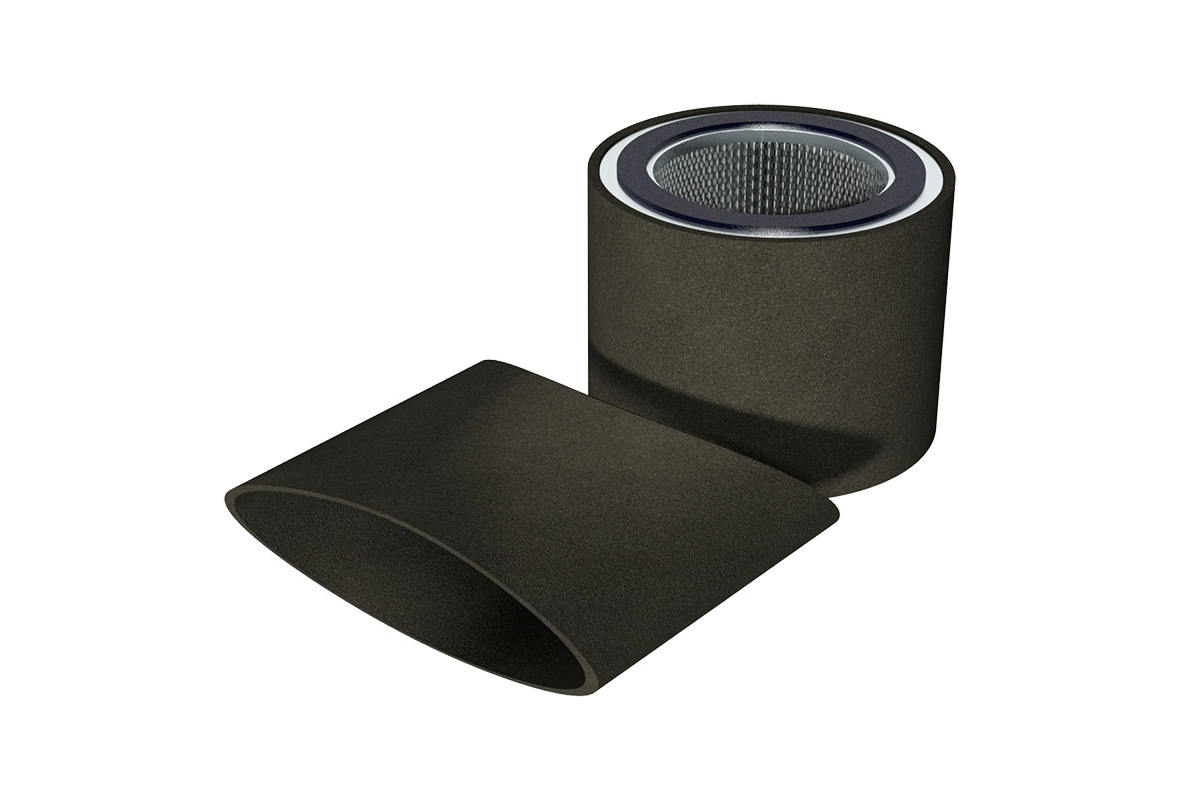

EFS Series: Compact Discharge Filter Silencer

The EFS Series provides filtration and silencer for discharge of dry pumps such as dry scroll and screw type pumps. The multi-stage noise reducing features includes a final stage sound absorbent insert. Typical noise attenuation depends on vacuum pump and application but can provide a dampening effect of up to 13 dba. Construction is corrosive resistant black powder coat carbon steel. Operational orientation can be horizontal or vertical.

- Dry Scroll, Piston, Vane and Venturi Vacuum Pumps

- Prevent tip seal dust and debris from contaminating the environment

- Silence irritating pump exhaust noise

Specifications

- Polyester: 99%+ removal efficiency to 25 micron

- Temp (continuous): min -15°F (-26°C) max 220°F (104°C)

- Seamless drawn housings-no welds to rust or vibrate apart

- Durable carbon steel construction with black powder coated

finish - Ability to mount vertically, horizontally

DSV/DEE Series: Oil Mist & Odor Filters

The Solberg DSV is an extremely effective vacuum pump discharge filter that offers two stages of filtration to remove both oil mist and undesirable odors from the pump’s exhaust. It offers a compact, straight-through design, with an integrated drain port (DEE Series includes back pressure valve) to easily evacuate any collected contaminates. This innovative two-stage design starts with a proprietary coalescing media that cleans the discharge air by capturing and coalescing oil mist. The oil free air is then directed through an adsorptive activated carbon cartridge to remove any residual vapors or odors. The DSV was designed to be easily disassembled and serviced without the use of tools, allowing for extremely fast filter change-out and minimal downtime.

- Oil mist elimination

- Odor adsorption

- Reduce overall maintenance costs

- Contamination removal

Specifications

- 0.3 micron media; 99.97% efficiency

- Continuous operating temp: 32°F (0°C) to 180°F (80°C)

- DEE Series: back pressure valve at 7.35 PSI differential for pump safety

EE Series: Recirculating Oil Mist Filter

The EE Series recirculating oil mist filter is used for oil mist removal in oil filled vacuum pump exhaust. The compact low profile design promotes high efficiency while low in maintenance. It is equipped with a back pressure valve designed to release element at 0.5 bar (7.35 PSI) differential for pump safety. The EE Series has a seamless drawn housing with white corrosive resistant painted carbon steel to promote a long working lifetime. The oil drain is a 1/8” NPSC fitting.

- Compact, low profile design

- Easy field maintenance

Specifications

- 0.3 micron media; 99.97% efficiency

- Continuous operating temp: 32°F (0°C) to 180°F (80°C)

- DEE Series: back pressure valve at 7.35 PSI differential for pump safety

- Mounted vertically

EF Series: Small Vacuum Pump Oil Mist Filter

The EF Series recirculating oil mist filter is used for oil mist removal in oil filled vacuum pump exhaust. The very compact design promotes high efficiency of 99.97% effectiveness (with 0.3 micron media) while requiring low maintenance. Vacuum oil captured by the filter drains back into the oil reservoir. Construction is steel with nickel plated finish. Equipped with easy thumb screw access for filter element maintenance, the EF Series is an excellent choice for smaller vacuum pump installations.

- Captures oil fog, mist or aerosol from discharge of oil sealed vacuum pumps

- Steel construction with nickel plated finish

- Seamless drawn housings

- Easy thumb screw access for element maintenance

- Oil run-off from the filter returns to the pump

Specifications

- 0.3 micron media; 99.97% efficiency

- Continuous operating temp: 68°F (20°C) to 180°F (80°C)